Plant Requiring Certificate of Fitness Regulations 2024

Key Information

Regulations made to govern the certification, inspection, and safe operation of plants such as steam boilers, pressure vessels, and lifting machinery requiring a Certificate of Fitness when installed at the workplace.

Source: DOSH - P.U. (A) 99

PART I - PRELIMINARY

Regulation 1. Citation and commencement

(1)

These regulations may be cited as the Occupational Safety and Health (Plant Requiring Certificate of Fitness) Regulations 2024.

(2)

These Regulations come into operation on 1 June 2024.

Regulation 2. Interpretation

In these Regulations—

“authorized inspecting body” means any entity listed in the First Schedule;

“safe working load” means the maximum load of lifting machinery as specified in the design verification approved under paragraph 4(1)(a);

“pressure vessel” means an enclosed vessel with pressure greater or less than atmospheric pressure;

“steam boiler” means any closed vessel for any purposes which steam is generated under pressure greater than atmospheric pressure and includes any economiser used to heat water being fed to the vessel and any super heater used for heating steam and any pipes and fittings connected to the closed vessel;

“launching gantry” means a lifting machinery which is a lifting device and a supporting structure for lifting precast beams and precast bridge segments in position for assembling or consists of main trusses and lifting devices that move horizontally along the trusses when lifting the precast beam, bridge segments or working platforms for assembling;

“lifting machinery” means any equipment for lifting, raising, transporting or lowering loads;

“suspended access equipment” means a lifting machinery which is access system comprising one or more overhead fixed or temporary support, one or more suspension lines, hoisting devices and working platform that can be moved vertically;

“material handling equipment” means a lifting machinery which is power-driven equipment for handling material, and includes forklift, conveyor, automated storage retrieval system, excavator, tractor, dumper or bulldozer;

“funicular railway” means a lifting machinery which is an engineering system for the transport of passengers or goods on slope area using carriers or vehicles that move along the rails and drawn by a rope at one end together with any other machinery, equipment or plant connected therewith;

“crane” means a lifting machinery, not including lifting tackle, which—

(a)

is a powered device equipped with mechanical means for raising or lowering loads suspended by a hook or other load handling device which can reposition or move a suspended load vertically or horizontally by the movement of the crane or the boom, jib, trolley or other such part of the crane; and

(b)

includes all parts of the crane including wire ropes, hook or load handling device, or any other device used to move the hook;

“mobile crane” means a lifting machinery which is a crane with a power-driven equipment mounted on a wheels or crawler base, and its primary functions are to raise, lower and swing loads at various radius by lifting tackle suspended from a lattice or telescopic boom;

“quay crane” means a lifting machinery which is a crane installed at quay used to raise or lower containers and move on a fixed runway;

“overhead travelling crane” means a lifting machinery which is a crane with a girder equipped with a device for raising and lowering loads and move on a fixed runway;

“tower crane” means a lifting machinery which is a crane with a boom or jib which is mounted on a vertical tower to raise and lower a suspended load and for the movement of such loads by changing the radius or slewing;

“walkalator” means a lifting machinery for the conveyance of person in which the user carrying surface remains parallel to each direction of motion and is uninterrupted;

“lift” means a lifting machinery with traction, positive or hydraulic drive, functioning at specific levels and having a carrier moving along guides which are rigid and inclined at an angle of more than 15 degrees to the horizontal, or along a fixed course even where it does not move along rigid guides, for the purposes of the transportation of persons only, or persons and goods, but it does not include lifts with rated speed less than 0.15 meter per second;

“plant requiring certificate of fitness” means all plants as prescribed under regulation 3;

“aerial working platform” means a lifting machinery which is a mechanical equipment designed to elevate persons for the purposes of working at height by means of a platform supported by scissor, mast or boom methods;

“owner” means a person who receives rent or profit by leasing any of the plant requiring certificate of fitness whether on his own account or as an agent or trustee for any other person;

“hoist” means a lifting machinery which is a passenger hoist and a material hoist;

“material hoist” means a lifting machinery consisting of hoist equipment, guides and support structures which is attached to the building either permanent or temporary and used to raise and lower material;

“passenger hoist” means a lifting machinery consisting of hoist equipment, guides and support structures which is attached to the building either permanent or temporary and used to raise and lower person or, person and material;

“origin manufacturer” means an original manufacturer of any imported steam boiler, pressure vessel or lifting machinery;

“alteration” means any alteration to—

(a)

the design that may affect the strength, integrity or functional capability of any of the plant requiring certificate of fitness

(b)

the safe working pressure for steam boilers and pressure vessels

(c)

the safe working load for lifting machinery; or

(d)

the travel distance, size, rated speed or rated load for lifts;

“heating surface” means, in respect of a steam boiler, the total surface of all plates and tubes exposed to heat on one side and in contact with water on the other, measured on the water or fireside, whichever is the greater, and excluding the heating surface of any economiser and superheater connected to it;

“recognized standard” means a standard as specified in the Fourth Schedule;

“lifting tackle” means any device used directly or indirectly to connect a load to lifting machinery but not permanently attached to the load, including a chain sling or rope, shackle, link, hook, swivel, eye bolt, chain, rope, pulley block and chain block;

“safe working pressure” means the maximum permissible pressure at which a steam boiler or pressure vessel may be operated as specified in the design verification issued under paragraph 4(1)(a);

“design verification” means a document issued by Director General containing particulars of description to certify that the design of any of the plant requiring certificate of fitness complies with the recognized standard;

PART II - PLANT REQUIRING CERTIFICATE OF FITNESS

Regulation 3. Prescription of plant requiring certificate of fitness

The following plants are prescribed as plants requiring certificate of fitness:

(a)

steam boiler;

(b)

pressure vessel; and

(c)

lifting machinery.

PART III - INSTALLATION OF PLANT REQUIRING CERTIFICATE OF FITNESS

Regulation 4. Requirement for installation of plant requiring certificate of fitness

(1)

Any person who installs or causes to be installed any plant requiring certificate of fitness shall comply with the following requirements:

(a)

make an application to the Director General to obtain design verification for any plant requiring certificate of fitness by submitting technical documents and particulars as specified in the Fifth Schedule together with the payment of fee as specified in the Sixth Schedule;

(b)

for the purposes of an application under paragraph (a)—

(i)

where the plant requiring certificate of fitness is manufactured in Malaysia, the application shall be made by a manufacturer who is a competent person; and

(ii)

where the plant requiring certificate of fitness is manufactured outside Malaysia, the application may be made by any person.

(c)

ensure that the design, substance, construction, performance quality, inspection and testing of the plant requiring certificate of fitness comply with the recognized standard;

(d)

ensure that the plant requiring certificate of fitness manufactured in Malaysia is manufactured by a competent person;

(e)

ensure that the plant requiring certificate of fitness is new or has never suffered from any deterioration if the plant requiring certificate of fitness is manufactured outside Malaysia;

(f)

in relation to any used plant requiring certificate of fitness imported into Malaysia—

(i)

submit any record of previous use;

(ii)

submit a record verifying that the plant requiring certificate of fitness has never suffered from any deterioration due to any cause;

(iii)

submit an integrity report certified by the authorized inspecting body on the inspection and testing of the plant requiring certificate of fitness;

(iv)

submit a report certified by the authorized inspecting body on the remnant life of the plant requiring certificate of fitness; and

(v)

submit a manufacturer's data report;

(g)

where the plant requiring certificate of fitness is a steam boiler or lifting machinery as specified in the Seventh Schedule, ensure that the steam boiler or lifting machinery is installed by a competent person or an origin manufacturer;

(h)

ensure the foundation for the installation of any plant requiring certificate of fitness is adequately designed and constructed to support and withstand the load imposed on it;

(i)

ensure the plant requiring certificate of fitness is equipped with essential fittings which comply with the requirements as specified in the Eighth Schedule;

(j)

ensure the plant requiring certificate of fitness complies with the recognized standard;

(k)

ensure the plant requiring certificate of fitness is tested or examined as specified in the design verification;

(l)

where the application is in relation to the installation of tower crane or passenger hoist, ensure the examination of foundation, structural integrity and component integrity is carried out by a competent person before installation;

(m)

where the application is in relation to the installation of a suspended access equipment, quay crane or launching gantry, ensure that the inspection of structural integrity and component integrity is carried out by a competent person before installation; and

(n)

obtain the required test and examination reports with the particulars as specified in the Ninth Schedule.

(2)

Where the requirements under subregulation (1) have been complied with, any person may apply for written approval for the installation of a plant requiring certificate of fitness from the Director General in the form and manner as determined by the Director General.

(3)

In the case of a plant requiring certificate of fitness which has been issued certificate of fitness for a specific location but will be relocated to a new location, any person who intends to install the plant at the new location shall apply for written approval for the installation of the plant according to subregulation (2) and shall comply with all requirements in subregulation (1) except paragraphs (1)(a) to (f).

PART IV - CERTIFICATE OF FITNESS AND INSPECTION

Regulation 5. Certificate of fitness

(1)

For the purposes of an inspection to obtain a certificate of fitness under subsection 27D(2) of the Act, an officer or licensed person shall issue a certificate of fitness to the person upon all requirements under subregulation 4(1) are complied with and upon payment of the fee as specified in the Sixth Schedule.

(2)

An inspection under subregulation (1) shall be carried out subject to the following requirements:

(a)

the owner shall make preparation for the inspection of the plant requiring certificate of fitness;

(b)

where a steam boiler is inspected, a functional test on all safety devices of the steam boiler when the steam boiler is operated at safe working pressure shall be carried out;

(c)

where a pressure vessel is inspected, a functional test on all safety devices of the pressure vessel shall be carried out; and

(d)

where lifting machinery is inspected, a load test at the load specified in the design verification and a functional test on all safety devices of the lifting machinery shall be carried out.

(3)

If an officer or licensed person finds that a plant requiring certificate of fitness does not comply with any of the requirements under subregulation (2), the person who intends to operate or cause or permit to be operated of any plant installed under section 27C of the Act shall pay to the officer or licensed person the fee as specified in the Sixth Schedule for the services rendered even though there is no certificate of fitness issued upon inspection.

(4)

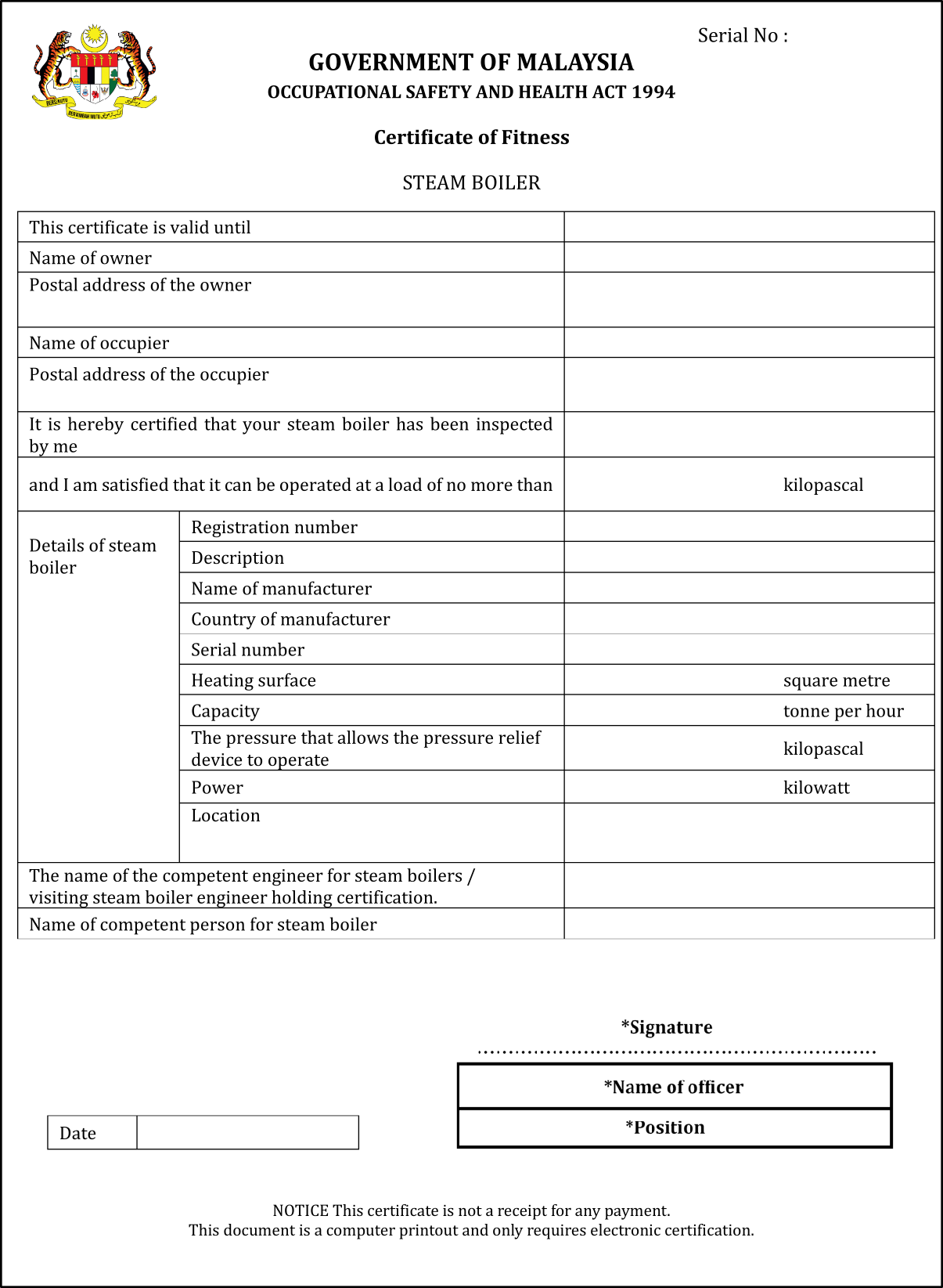

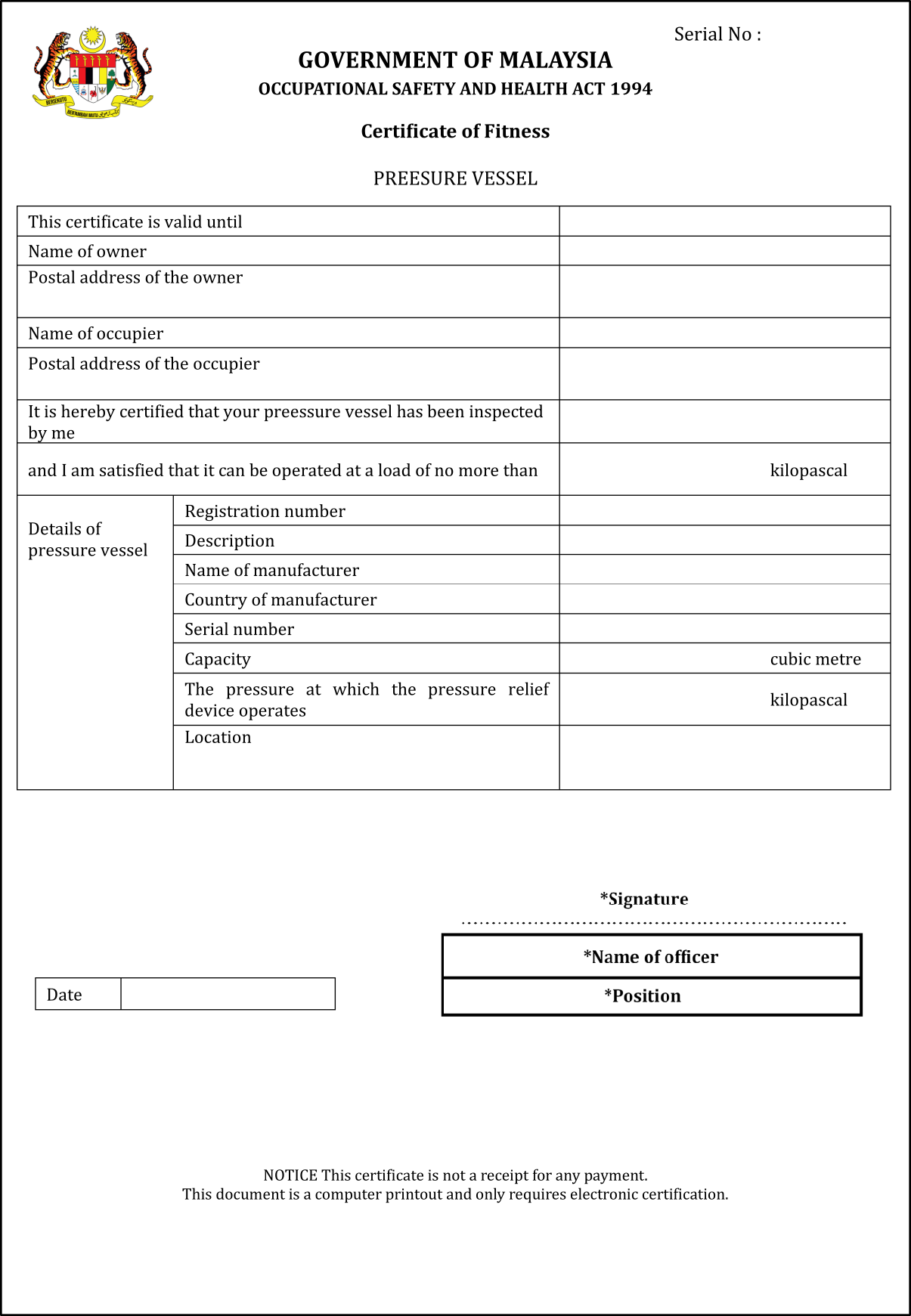

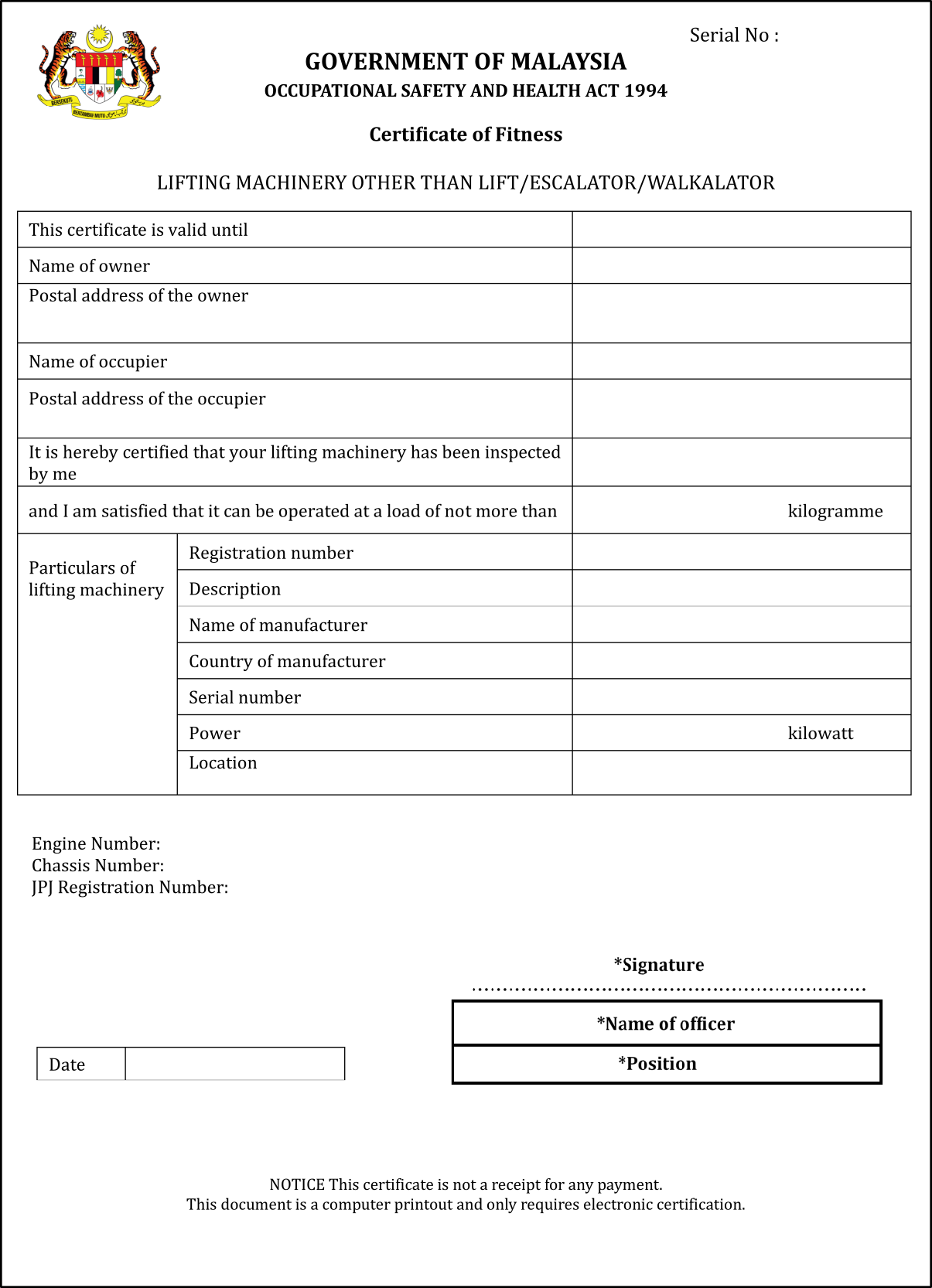

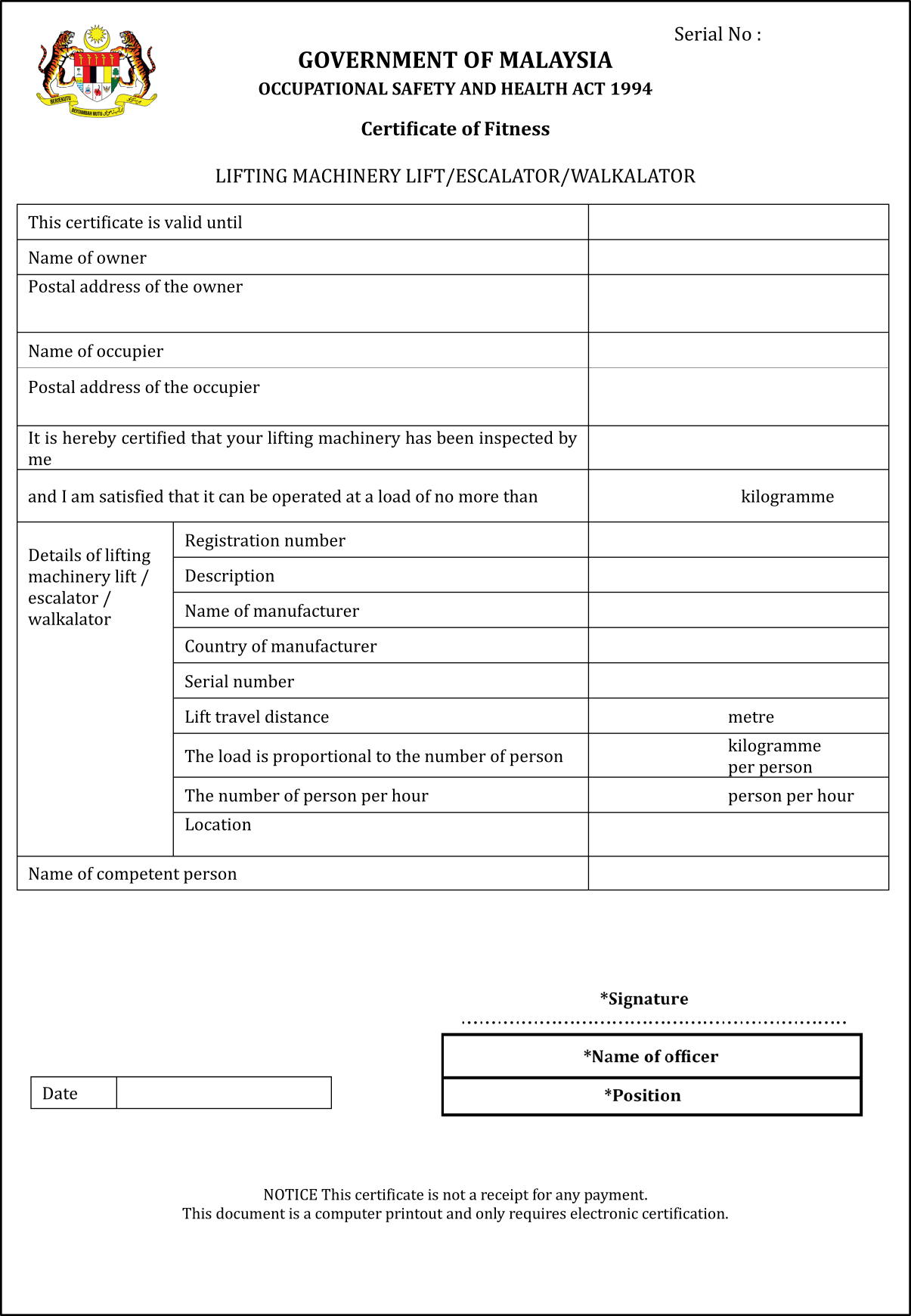

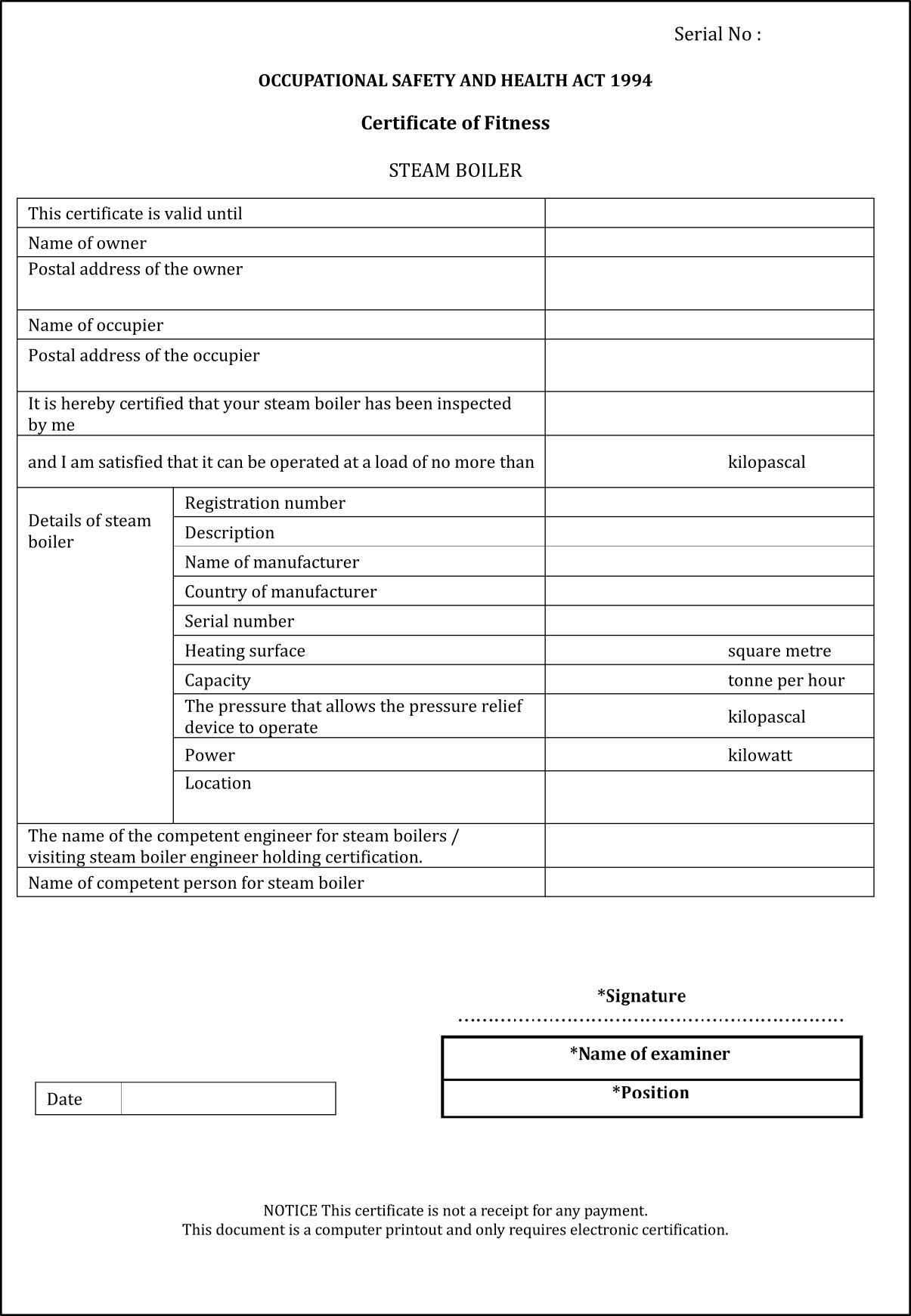

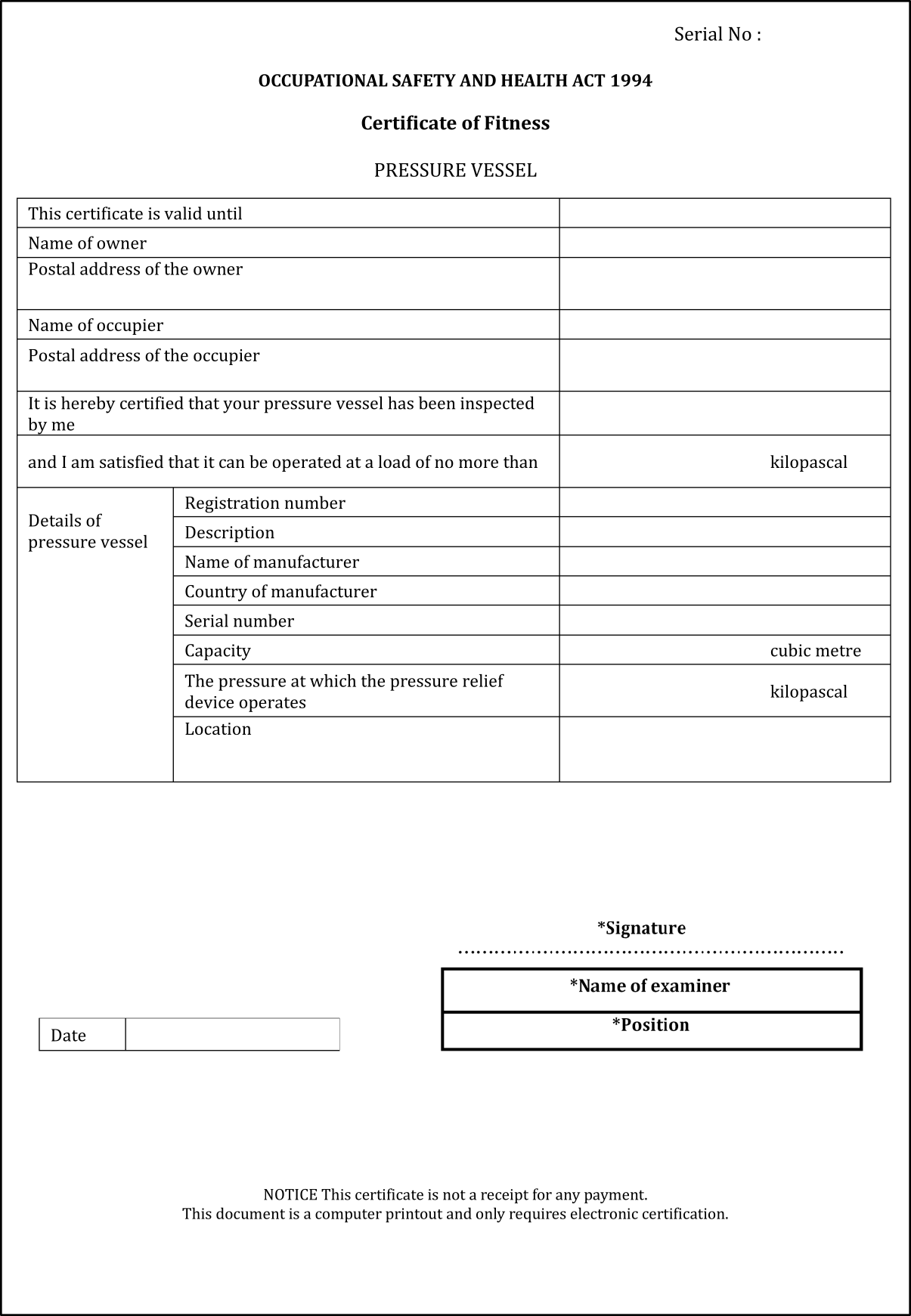

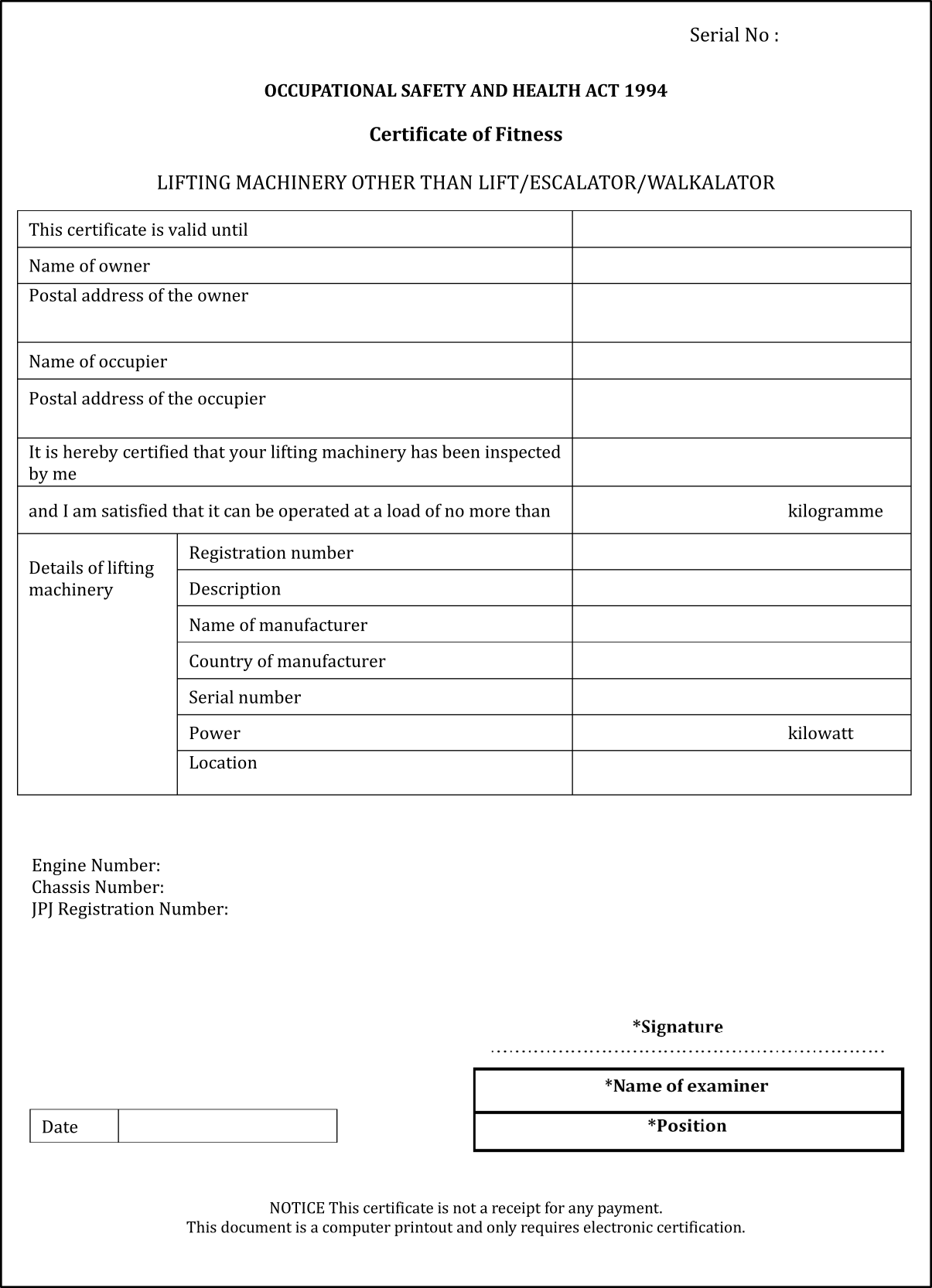

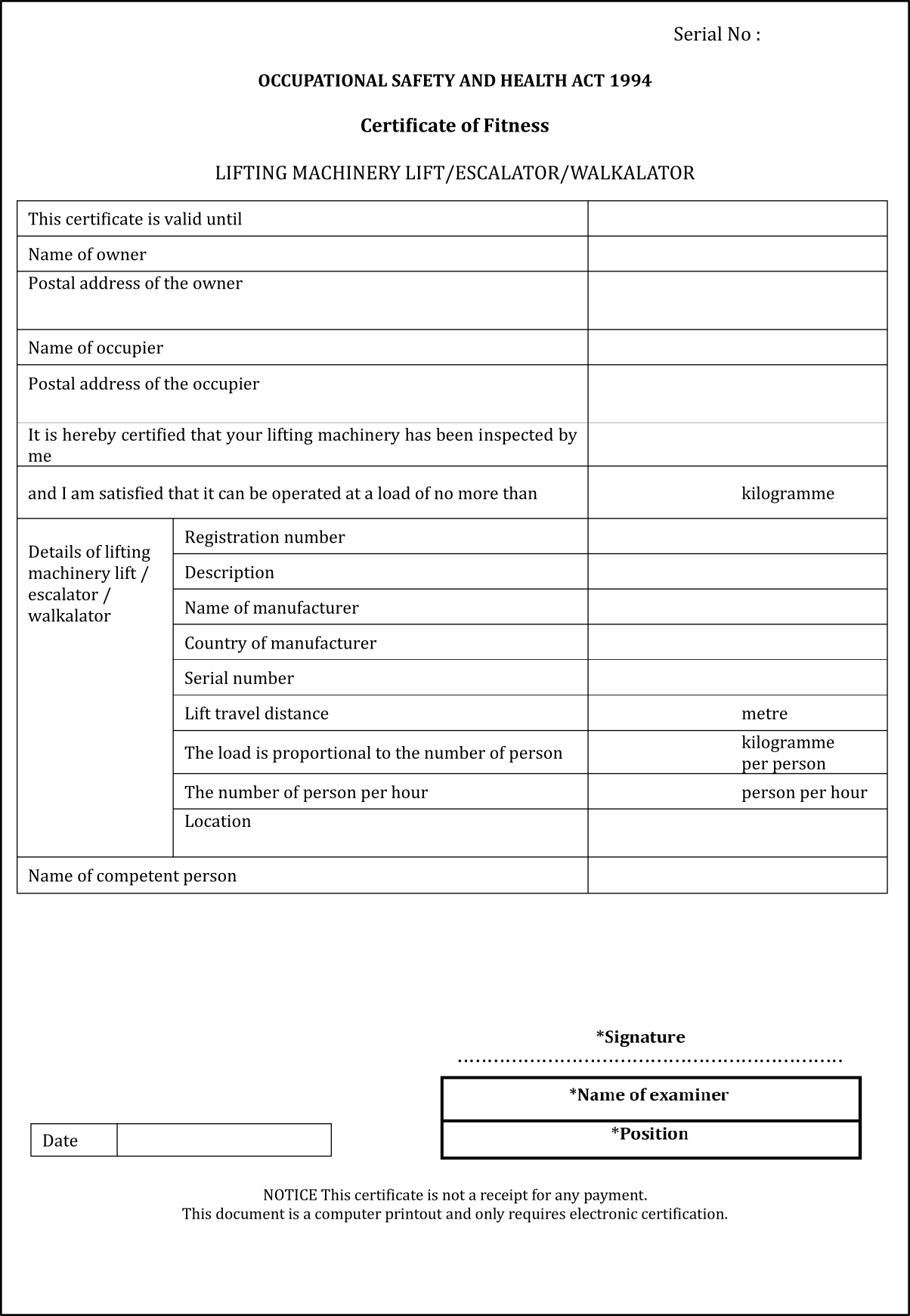

A certificate of fitness shall be issued in the form as specified in the Tenth Schedule.

(5)

A certificate of fitness shall be subject to the following terms and conditions:

(b)

the certificate of fitness for any plant requiring certificate of fitness which operates in portable form without being dismantled shall remain valid even though the plant is relocated after the certificate of fitness has been issued;

(c)

where an owner sells, leases, transfers or disposes of a plant requiring certificate of fitness, the owner shall notify the officer or licensed person within thirty days after the sale, lease, transfer or disposal; and

(d)

where an owner finds that his plant requiring certificate of fitness has fallen into disuse, the owner shall notify the officer or licensed person within thirty days of becoming aware that the plant has fallen into disuse.

(6)

The certificate of fitness issued under subregulation (1) shall be valid for a period of fifteen months from the date of inspection.

Regulation 6. Periodical inspection

(1)

Subject to regulation 5, a periodical inspection of plant requiring certificate of fitness under section 27E of the Act shall be carried out by an officer or a licensed person upon payment of the fee as specified in the Sixth Schedule.

(2)

The inspections under subregulation (1) shall be in accordance with the following manner:

(a)

an officer or licensed person may, at their discretion, determine the date of periodical inspection for any plant requiring certificate of fitness provided that the date is not earlier than the first day of the twelfth month after the month of the inspection under subsection 27D(2) of the Act or the last periodical inspection that was carried out;

(b)

an officer or licensed person may issue a written notice at least fourteen days before the date of the periodical inspection to an owner or occupier regarding his intention to carry out the periodical inspection;

(c)

without prejudice to paragraph (a), an owner or occupier may apply in writing to the officer or licensed person, not later than after the first day of the twelfth month of the inspection under subsection 27D(2) of the Act or the last periodical inspection that was carried out, to propose the date of the periodical inspection;

(d)

upon receiving notice under paragraph (b), the owner or occupier shall be responsible for the preparation for the periodical inspection by providing their plant requiring certificate of fitness for the periodical inspection according to the Act, regulations, recognized standard and any requirements that may be determined by the Director General;

(e)

any steam boiler shall be available for internal inspection at each periodical inspection;

(f)

any pressure vessel shall be available for internal inspection at each periodical inspection unless the pressure vessel has been designed not subject to internal inspection;

(g)

any lifting machinery except for lifts, escalators and walkalators shall be available to enable the lifting machinery to be tested under safe working load condition and to ensure that all safety devices are in good working condition;

(h)

any lifts, escalators and walkalator shall be available to enable lifts, escalators and walkalator to be tested to ensure that all safety devices are in good working condition; and

(i)

any plant requiring certificate of fitness that complies with all requirements under the Act, regulations, and recognized standard shall be issued a certificate of fitness by the officer or licensed person and shall be valid for a period of fifteen months from the date of inspection.

Regulation 7. Plant requiring certificate of fitness not available for periodical inspection

(1)

If a plant requiring certificate of fitness is not available for inspection during the periodical inspection visit under regulation 6, an officer or licensed person may refuse to carry out or complete the inspection of the plant and in such a case, the officer or licensed person shall inform the owner or occupier in writing of the reasons for the refusal.

(2)

The owner shall resubmit a written notice for the periodical inspection if the plant requiring certificate of fitness is not available for periodical inspection.

(3)

For the purposes of subregulations (1) and (2), a fee as specified in the Sixth Schedule shall be paid by an owner or occupier, as the case may be, for each visit of periodical inspection.

Regulation 8. Maintenance

(1)

An owner of a plant requiring certificate of fitness shall ensure that the plant requiring certificate of fitness is maintained at all times so that the plant is in a safe and in good working condition.

(2)

An owner shall ensure that lift, escalator, walkalator, tower crane, suspended access equipment, launching gantry, quay crane and passenger hoists are maintained by competent person according to the procedures as specified in the Eleventh Schedule.

(3)

An owner shall enter into an agreement with a competent person for the servicing, adjustment and comprehensive examination of lifts, escalators and walkalators, and the duration of the agreement shall not be less than one year.

Regulation 9. Repair

(1)

An owner or occupier shall give a written notice to the officer or licensed person before carrying out repairs on any plant requiring certificate of fitness.

(2)

An owner or occupier shall ensure that the repairs of any plant requiring certificate of fitness are carried out by a competent person in accordance with the requirement of the manufacturer, recognized standard or good engineering practice.

(3)

Any plant requiring certificate of fitness repaired under subregulation (2) shall be tested and examined as required by recognized standard and under the supervision of a competent person.

Regulation 10. Dismantling

(1)

The owner or occupier shall ensure that only competent persons are authorized to dismantle steam boiler and lifting machinery certificate of fitness as specified in the Seventh Schedule.

(2)

The owner or occupier who contravenes this subregulation (1) commits an offence and shall, on conviction, be liable to a fine not exceeding fifty thousand ringgit or to imprisonment for a term not exceeding one year or to both.

Regulation 11. Alteration

(1)

An owner shall not, unless written approval has been granted by the Director General, make or cause to be made any alteration to plant requiring certificate of fitness by submitting any details and documents as determined by the Director General.

(2)

An owner shall ensure any alteration to plant requiring certificate of fitness is carried out by any party specified in the approval granted under subregulation (1) according to the manufacturer's requirements, recognized standard or good engineering practice.

(3)

Each plant requiring certificate of fitness after completion of alterations shall be subjected to inspection under section 27D of the Act before being operated.

(4)

For the purpose of subregulation (1), every application for approval of alterations shall be accompanied with a processing fee as specified in the Sixth Schedule.

(5)

The owner who contravenes this regulation commits an offence and shall, on conviction, be liable to a fine not exceeding fifty thousand ringgit or to imprisonment for a term not exceeding one year or to both.

PART V - CONTROL AND OPERATION OF STEAM BOILER

Regulation 12. Control and operation of steam boiler

(1)

An owner or occupier shall ensure any steam boiler is under the control of a competent person who is a steam boiler engineer either employed or acting as a visiting steam boiler engineer as specified in the Twelfth Schedule.

(2)

An owner or occupier shall ensure any steam boiler is operated and be in charged by a competent person who is a steam boiler operator as specified in the Twelfth Schedule.

(3)

An owner or occupier shall notify the Director General in writing of any appointment or termination of a competent person who is a visiting steam boiler engineer within thirty days after such appointment or termination.

(4)

Subregulations (1), (2) and (3) shall not apply to—

(a)

electric steam boiler;

(b)

steam tube oven;

(c)

steam tube hot plate;

(d)

autoclave; and

(e)

any other steam boiler that retains the steam that it generates.

PART VI - USE, EXAMINATION AND OPERATION OF LIFTING MACHINERY

Regulation 13. Use of lift, escalator and walkalator

An owner or occupier shall comply with the requirements for the use of each lift, escalator and walkalator as specified in the Thirteenth Schedule.

Regulation 14. Comprehensive examination for specific lifting machinery

(1)

An owner or occupier shall ensure a comprehensive examination of each lift, escalator, walkalator, tower crane, passenger hoist, suspended access equipment, quay crane and launching gantry are carried out by a competent person at least once every three months or according to the period as specified in the manufacturer's manual, whichever is more frequent.

(2)

The competent person carrying out the comprehensive examination shall provide a comprehensive examination report with the particulars as specified in the Fourteenth Schedule.

(3)

Any owner or occupier who contravenes subregulation (1) commits an offence and shall, on conviction, be liable to a fine not exceeding one hundred thousand ringgit or to imprisonment for a term not exceeding one year or to both.

(4)

Any competent person who contravenes subregulation (2) commits an offence and shall, on conviction, be liable to a fine not exceeding five thousand ringgit or to imprisonment for a term not exceeding one year or to both.

Regulation 15. Operation of tower crane and mobile crane

(1)

The owner or occupier shall ensure that each tower crane or mobile crane is operated only by a competent person who is a crane operator.

(2)

The owner or occupier shall establish lifting plan by taking into account the risk assessment report so that the tower crane or mobile crane can be operated safely.

(3)

The competent person who is a crane operator who operates tower crane or mobile crane shall—

(a)

comply with any instruction or measure on occupational safety and health instituted by his employer or occupier related to the safe operation of tower crane or mobile crane during work;

(b)

carry out operational test on all limit switch and indicator device without any load before any lifting operation is carried out and the test results shall be recorded in the logbook or log sheet before the start of each work shift; and

(c)

ensure the ground condition especially the surface on which the mobile crane will be operated is safe for any movement or lifting operation, and if he deems it unsafe for any movement or lifting operation, he shall report the matter to the employer or occupier.

(4)

Any owner or occupier who contravenes subregulations (1) and (2) commits an offence and shall, on conviction, be liable to a fine not exceeding one hundred thousand ringgit or to imprisonment for a term not exceeding one year or to both.

(5)

Any competent person who contravenes subregulation (3) commits an offence and shall, on conviction, be liable to a fine not exceeding five thousand ringgit or imprisonment for a term not exceeding one year or both.

Regulation 16. Use of lifting tackle

(1)

No person shall use any lifting tackle on lifting machinery unless the design and construction of the lifting tackle comply with recognized standard.

(2)

The owner or occupier shall, so far as is practicable, to ensure that the lifting tackle is in good condition before using it on lifting machinery.

PART VII - MISCELLANEOUS

Regulation 17. Payment of fees

(1)

Any fee paid under these Regulations shall not be refundable.

(2)

The Government is exempted from making payment for the inspection of plant requiring certificate of fitness operated and owned by the Government.

Regulation 18. Marking of plant

The owner of any plant requiring certificate of fitness shall make a marking of the registration number and display prominently on the plant.

Regulation 19. Record

(1)

An employer shall keep and maintain records of the maintenance of plants requiring certificate of fitness.

(2)

The records of the maintenance referred to in subsection (1) shall contain the following details:

(a)

the condition and effectiveness of any essential fittings or safety devices installed on plant requiring certificate of fitness;

(b)

particulars of any damages that may occur; and

(c)

information regarding repairs and alterations.

Regulation 20. Record or document to be kept by employer

An employer shall provide at the place of work, information and documents related to design verification, construction, installation, operation and records of testing, inspection, repair, alteration, maintenance and comprehensive examination of plants requiring certificate of fitness in the national language or English language that can be easily understood.

Regulation 21. Non-application

These Regulations shall not apply to—

(a)

the pressure vessel as specified in the Second Schedule; and

(b)

the manual lifting machinery and lifting machinery as specified in the Third Schedule.

SCHEDULES

FIRST SCHEDULE [Regulation 2] - AUTHORIZED INSPECTING BODY

List of authorized inspecting body

1.

All members of the Vereinigung der Technishen Uberwachungs- Vereine e.V

2.

Apave SA, France

3.

Apave TIV Malaysia Sdn Bhd

4.

Associated Offices Technical Committee, Manchester 3, Great Britain

5.

Association des Industriels de Belgique (A.I.B), Brussels, Belgium

6.

Authorized inspecting body listed under the European Union for carrying out compliance assessments according to the Council Directive

7.

Bataafse Internationale Petroleum Maatschappij NV., Holland

8.

British Engineering Services Limited

9.

Bureau Veritas International Register of Shipping, Paris

10.

C & P SRL

11.

DNV GL AS

12.

HSB Inspection Quality Limited, United Kingdom

13.

HSB Of Connecticut, U.S.A

14.

International Business & Mercantile Reassurance Company

15.

Intertek Testing Services (Japan) K.K

16.

Japan Boiler Association, Tokyo

17.

Japan Inspection Company Ltd., Tokyo

18.

Kiwa Sweden AB, Sweden

19.

Koatsugase Hoan Kyokai (KHK), Japan

20.

LRQA VERIFICATION LIMITED, London

21.

Moody International Ltd. (M.M.I), United Kingdom

22.

New Zealand Marine Department

23.

Nippon Kaiji Kyokai, Japan

24.

OneCis Insurance Company, USA

25.

Plant Safety Limited, United Kingdom

26.

Registro Italiano Navale (RINA), Italy

27.

S.G.S Far East Ltd

28.

Schweizerischer Verein Fur Technische Inspektionen (SVTI)

29.

Shanghai Institute of Special Equipment Inspection and Technical Research, Shanghai, People Republic of China

30.

SIRIM QAS International Sdn. Bhd. Malaysia

31.

Societe Generale de Surveillance

32.

Stiching Independent Inspectors Pool, Holland (Shell Group of Companies)

33.

Technical Standards and Safety Authority, Ontario, Canada

34.

The Royal Danish Boiler Inspection Department

35.

TUV Industrie Service GmbH, TUV Rheinland Group, Cologne

36.

TUV Suddeutschland Group, Munich

37.

Velosi Certification Bureau Limited, United Kingdom

38.

Vincotte International, Belgium

39.

Zurich Risk Services, United Kingdom

SECOND SCHEDULE [Paragraph 21(a)] - PRESSURE VESSEL

1.

A pressure vessel having an internal or external design pressure not exceeding fifteen pounds per square inch (15 PSIG) regardless of the size of the pressure vessel.

2.

A pressure vessel having an internal diameter, width, height or cross section diagonal not exceeding six inches regardless of the length or pressure of the pressure vessel.

3.

A pressure vessel containing water under pressure having a design pressure not exceeding three hundred pounds per square inch (300 PSIG) and a design temperature not exceeding ninety-nine degrees Celsius (99°C).

4.

A pressure vessel with two or more chambers having an internal or external design pressure on each chamber not exceeding fifteen pounds per square inch (15 PSIG) and the differential pressure between each chamber not exceeding fifteen pounds per square inch (15 PSIG) regardless of the size of pressure vessel.

5.

A pressure vessel with its piping component or an accessory of the piping component which function is to mix, separate, snub, distribute or control the flow of medium in the piping component or accessory of the piping component.

6.

A pressure vessel which is a component of a rotating or reciprocating mechanical device which functions is to support the operation of the mechanical device.

7.

A pressure vessel which is a plate heat exchanger or spiral heat exchanger.

8.

A pressure vessel which becomes a component of a chiller package for a building.

9.

Pressure vessel which is inside a complete cold box package which is an aluminium heat exchanger soldered which consists in a carbon steel shell with structural supports, insulation containment and protection for internal tools.

10.

Pressure vessel which is a gas cylinder used for the storage and transportation of compressed, dissolved and liquefied gases.

THIRD SCHEDULE [Paragraph 21(b)] - LIFTING MACHINERY

1.

Lifting machinery for material handling equipment.

2.

Lifting machinery used for the purpose of drilling or digging holes in the ground or to make wells such as drilling rigs or drilling rigs.

3.

Lifting machinery used to drive piles or bore piles into the ground to construct pier, bridge, dam and other pier-supported structures as part of the permanent foundation of a building or other structure mounted on a chain wheel.

4.

Lifting machinery which is the winch installed on a vehicle.

5.

Lifting machinery which is installed as a dock leveller which is a permanent equipment placed at the dock door which is used to raise or lower the dock level.

6.

Lifting machinery installed as ergonomic lifting aid equipment to help workers lift, move the position of goods or loads that are too heavy to be done manually such as manipulators.

7.

Lifting machinery which is used as a platform or elevated walkway which provides a walkway such as a walkway tower.

8.

Lifting machinery which is a vertical conveyor used to move or transport a load in a predetermined route and has a point of loading and unloading the load, at a fixed or selective position.

9.

Lifting machinery which is mechanical equipment permanently installed at the back of the vehicle and designed to handle loads from the ground level or loading dock to the floor level of the vehicle, or vice versa.

10.

Lifting machinery which becomes an equipment with automatic storage and retrieval system.

11.

Lifting machinery which is a crane whose lifting height not exceeding nine meters and whose maximum working load not exceeding eighty kilogrammes.

12.

Lifting machinery which uses air or pneumatics and its maximum working load not exceeding five hundred kilogrammes.

FOURTH SCHEDULE [Regulation 2] - RECOGNIZED STANDARDS

List of recognized standards

1.

AD Merkblatter Technical Rules

2.

American National Standards Institute (ANSI)

3.

American Petroleum Institute Standards (API)

4.

Australian Standards (AS)

5.

British Standards (BS)

6.

Deutsches Institut fur Normung (DIN)

7.

European Committee for Electrotechnical Standardization (CENELEC)

8.

Indian Boilers Regulations

9.

International Electrotechnical Commission Standard (IEC)

10.

International Organization for Standardization (ISO)

11.

New Zealand Standards (NZS)

12.

Nippon Kaiji Kyokai

13.

Malaysian Standards (MS)

14.

Standards of The Tubular Exchanger Manufacturers Association (TEMA)

15.

Swedish Pressure Vessel Code

16.

The American Society of Mechanical Engineers (ASME)

17.

The European Committee for Standardisation (CEN)

FIFTH SCHEDULE [Paragraph 4(1)(a)] - DOCUMENTS TO BE SUBMITTED FOR DESIGN VERIFICATION OF PLANT REQUIRING CERTIFICATE OF FITNESS

The following documents shall be submitted in national language or English language for the purposes of an application for design verification:

1.

STEAM BOILER DESIGN VERIFICATION

(a)

design appraisal certificate from an authorized inspecting body;

(b)

design drawings verified by an authorized inspecting body;

(c)

design calculations using the latest edition of recognized standards and verified by an authorized inspecting body;

(d)

piping and instrumentation diagram for autoclave and electric steam boiler;

(e)

name plate for autoclaves and electric steam boilers;

(f)

catalogue for imported autoclaves and electric steam boilers;

(g)

verification of authorized inspecting body is not required for design drawings and design calculations of autoclaves.

2.

PRESSURE VESSEL DESIGN VERIFICATION

(a)

design drawings;

(b)

design calculations using the latest edition of recognized standards;

(c)

plans and design calculations for imported pressure vessels which the multiple of an internal diameter with the design pressure measured in pounds per square inch is three thousand or more shall be verified by the authorized inspecting body.

3.

LIFTING MACHINERY DESIGN VERIFICATION

(1)

Lift, escalator and walkalator

(a)

design drawings;

(b)

design calculation using the latest edition of recognized standards;

(c)

certificate and test report of safety components verified by an authorized inspecting body;

(d)

certificate and test report of lift system for the model verified by an authorized inspecting body;

(e)

complete particulars of safety features according to recognized standards;

(f)

certificate and report of wire rope from the wire rope manufacturer.

(2)

Crane, hoist, suspended access platform, launching gantry, funicular railway and aerial working platform

(a)

design drawings;

(b)

design calculations using the latest edition of recognized standards;

(c)

catalogue or technical specifications for mass production;

(d)

load charts for mobile cranes, tower cranes, and aerial work platforms;

(e)

complete particulars of safety features according to recognized standards;

(f)

where the crane, hoist, suspended access platform, launching gantry, funicular railway and aerial working platform are imported—

(i)

type inspection certificate for systems and reports verified by the authorized inspecting body for imports;

(ii)

test certificate by manufacturer;

(iii)

manufacturer's certificate issued by the manufacturer.

(g)

wire rope or chain test certificate, if applicable.

(3)

Lifting machinery other than lift, escalator, walkalator, crane, hoist, suspended access platform, launching gantry, funicular railway and aerial working platform

(a)

design drawings;

(b)

design calculations using the latest edition of recognized standards;

(c)

catalogue or technical specifications for mass production;

(d)

load charts for mobile crane, tower crane and aerial work platform;

(e)

complete particulars of safety features according to recognized standards;

(f)

for imported lifting machinery—

(i)

test certificate by manufacturer;

(ii)

manufacturer's certificate issued by the manufacturer.

(g)

wire rope or chain test certificate, if applicable.

SIXTH SCHEDULE [Paragraph 4(1)(a) and subregulations 5(1), 5(3), 6(1), 7(3) and 11(4)] - FEES

SEVENTH SCHEDULE [Paragraph 4(1)(g) and subregulation 10(1)] - INSTALLATION OR DISMANTLE BY COMPETENT PERSON FOR STEAM BOILER OR LIFTING MACHINERY

1.

Any steam boiler or its component which requires construction and installation, other than maintenance, on site

2.

Lift

3.

Escalator

4.

Walkalator

5.

Hoist

6.

Tower crane

7.

Overhead travelling crane or overhead travelling crane monorail type which uses a girder consisting of either standard beam of type I or H with a safe working load exceeding 4,000 kilogrammes

8.

Quay crane

9.

Suspended access equipment

10.

Launching gantry

EIGHTH SCHEDULE [Paragraph 4(1)(i)] - ESSENTIAL FITTINGS

1.

The essential fittings related to steam boilers shall include:

(a)

pressure relief valve;

(b)

steam pressure gauge;

(c)

water level gauge;

(d)

low water alarm;

(e)

blowdown valve; and

(f)

manufacturer's name plate.

2.

The essential fittings related to pressure vessels shall include:

(a)

pressure relief valve;

(b)

pressure gauge; and

(c)

manufacturer's name plate.

3.

All essential fittings and any pipes connected to steam boilers and pressure vessels shall be designed, constructed and tested according to recognized standard.

NINTH SCHEDULE [Paragraph 4(1)(n)] - PARTICULARS OF TEST AND EXAMINATION REPORT

1.

Particulars of test report

The particulars shall include the following information:

(1)

Type of plant requiring certificate of fitness (steam boiler/pressure vessel)

(2)

Name of plant requiring certificate of fitness

(3)

Type of pressure test

(4)

Holding time (not less than 20 minutes)

(5)

Name and address of manufacturer

(6)

Design verification number

(7)

Design verification date

(8)

Name of owner

(9)

Address of owner

(10)

Name of occupier

(11)

Address of occupier

(12)

Year of manufacture

(13)

Date of pressure test

(14)

Location of pressure test

(15)

Design pressure (kilopascal (kPa))

(16)

Safe working pressure (kilopascal (kPa))

(17)

Capacity in cubic metre for pressure vessel

(18)

Heating surface in square metre for steam boiler

(19)

Type of steam boiler (fire tube/water tube/electric steam boiler/autoclave)

(20)

Applied pressure test

(21)

Serial numbers of plant requiring certificate of fitness

(22)

Name of recognized standard

(23)

Pressure test result

(24)

Name of the authorized inspecting body inspector who witnessed the stress test

(25)

Signature of the authorized inspecting body inspector who witnessed the stress test

(26)

Date of the issuance of pressure test certificate

2.

Particulars of examination report

The particulars shall include the following information:

(1)

Type of plant requiring certificate of fitness (lifting machinery namely tower crane/passenger hoist/suspended access equipment/quay crane/launching gantry)

(2)

Type of test (foundation integrity, structural integrity and component integrity)

(3)

Name of plant requiring certificate of fitness

(4)

Name of recognized standard

(5)

Year of manufacture

(6)

Serial number of plant requiring certificate of fitness

(7)

Name and address of the manufacturer

(8)

Design verification number

(9)

Design verification date

(10)

Safe working load

(11)

Maximum working radius (if applicable)

(12)

Name of owner

(13)

Address of owner

(14)

Name of occupier

(15)

Address of occupier

(16)

Location of installed machinery

(17)

Original type and size of wire rope/chain

(18)

Status and size of wire rope/chain (latest)

(19)

Type and status of lifting tackle used

(20)

List of safety devices installed

(21)

Structural defect (if applicable)

(22)

Examination reviews

(23)

Examination results

(24)

Name and signature of the issuer of the examination report

TENTH SCHEDULE [Subregulation 5(4)] - CERTIFICATE OF FITNESS

1. Certificate of fitness for steam boiler issued by an officer

2. Certificate of fitness for pressure vessel issued by an officer

3. Certificate of fitness for lifting machinery issued by an officer

4. Certificate of fitness of lifting machinery for lift/escalator/walkalator issued by an officer

5. Certificate of fitness for steam boiler issued by a licensed person

6. Certificate of fitness for pressure vessel issued by a licensed person

7. Certificate of fitness for lifting machinery issued by a licensed person

8. Certificate of fitness for lifting machinery/lift/escalator/walkalator issued by licensed person

ELEVENTH SCHEDULE [Subregulation 8(2)] - MAINTENANCE PROCEDURES FOR LIFT, ESCALATOR, WALKALATOR, TOWER CRANE, SUSPENDED ACCESS EQUIPMENT, LAUNCHING GANTRY, QUAY CRANE AND PASSENGER HOIST

1.

Maintenance procedures for lift, escalator and walkalator shall be as follows:

(a)

service and adjustment shall be carried out not less than once a month;

(b)

cause a competent person for lift to carry out comprehensive examination not less than once every three months or at such intervals as specified in the manufacturer's manual, whichever is more frequent; and

(c)

prepare a comprehensive examination report containing information as specified in the Fourteenth Schedule and ensure the report is kept on the premises where the lift, escalator or walkalator is installed;

2.

Maintenance procedures for tower crane, suspended access equipment, launching gantry, quay crane and passenger hoist:

(a)

maintenance shall be carried out not less than once a month;

(b)

cause a competent person to carry out a comprehensive examination at least once every three months or at such intervals as specified in the manufacturer's manual, whichever is more frequent; and

(c)

prepare a comprehensive examination report containing information as specified in the Fourteenth Schedule and ensure the report is kept on the premises where the tower crane, suspended access equipment, launching gantry, quay crane or passenger hoist is installed.

TWELFTH SCHEDULE [Subregulations 12(1) and (2)] - COMPETENT PERSON FOR USE AND CONTROL OF STEAM BOILER

THIRTEENTH SCHEDULE [Regulation 13] - REQUIREMENTS FOR USE OF LIFT, ESCALATOR AND WALKALATOR

1.

Display a notice in a lift, escalator or walkalator on contact particulars of any person who may be contacted for any service disruption of the lift, escalator or walkalator.

2.

Ensure a lift machinery room and pit is only used for a lift, escalator or walkalator and equipment related to it.

3.

Prohibit any additional accessories to the existing components unless permitted by competent person.

4.

Where enclosure of a lift, escalator or walkalator forms an integral part of the building in which the lift, escalator or walkalator is installed, ensure the enclosure is well maintained.

5.

Display a guide in the lift on the way to use emergency button or call button when malfunctions occur to the lift.

6.

Display the following signage in a fixed location adjacent to the entrance of each lift machinery room:

BILIK JENTERA LIF - BAHAYA

LIFT MACHINERY ROOM - DANGER

DILARANG MASUK TANPA KEBENARAN

NO ENTRY WITHOUT PERMISSION

FOURTEENTH SCHEDULE [Subregulation 14(2)] - INFORMATION TO BE INCLUDED IN A COMPREHENSIVE EXAMINATION REPORT

A comprehensive examination report by a competent person for lifting machinery shall include the following information but not limited to:

1.

The name and address of the owner

2.

The name and address of the occupier

3.

The address of the premises at which the comprehensive examination was made

4.

Particulars related to the manufacture of lift, escalator, walkalator, tower crane, passenger hoist, suspended access equipment, quay crane and launching gantry

5.

The date of the last comprehensive examination was made

6.

The safe working load of the lift, escalator, walkalator, tower crane, passenger hoist, suspended access equipment, quay crane and launching gantry or the safe working load for the last configuration in which the comprehensive examination was made

7.

In relation to each comprehensive examination of lift, escalator, walkalator, tower crane, passenger hoist, suspended access equipment, quay crane and launching gantry—

(a)

identification of any part found to have a defect which is or may become a danger to persons, and a description of the defect;

(b)

particulars of any repair, renewal or alteration required to remedy a defect found to be a danger to persons;

(c)

in the case of a defect which is not yet but could become a danger to persons—

(i)

the time by which it may become such a danger; and

(ii)

particulars of any repair, renewal or alteration required to remedy it;

(d)

the date for the next comprehensive examination must be carried out; and

(e)

the date of the comprehensive examination.

8.

The name, address and registration numbers of the competent person making the report and the name and address of competent person

9.

The date of the report